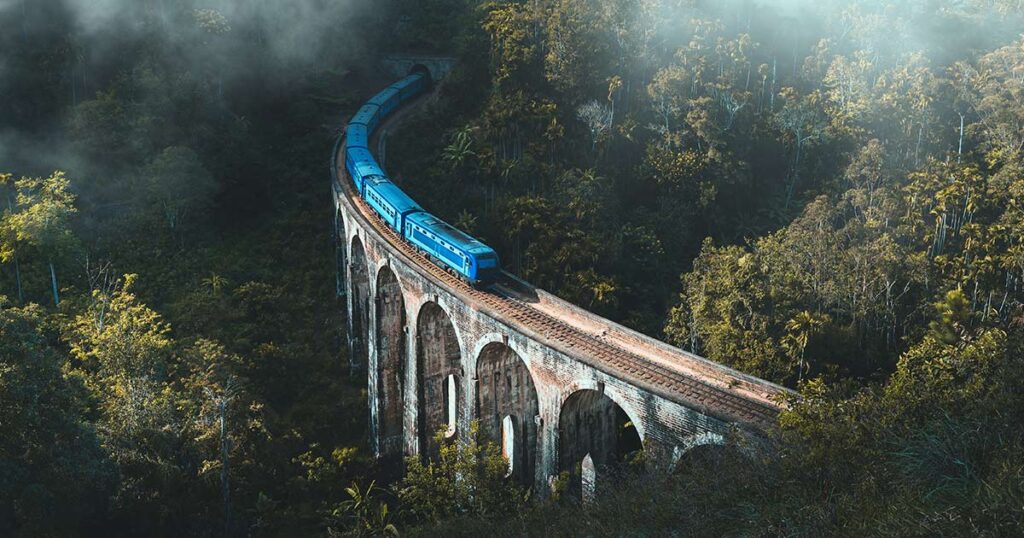

The Nine Arch Bridge, located on the Badulla Railway extension in Sri Lanka, connects Bandarawela to Badulla through mountainous terrain. This remarkable viaduct, spanning 400 feet with a maximum height of 100 feet 6 inches, features nine 30-foot spans and semi-circular arches.

The bridge was designed to accommodate a challenging nine-degree curve and steep gradient. Built entirely by local labor under British supervision, the construction faced significant logistical challenges, including difficult terrain and material transport. Completed in 1919, the bridge has since stood resilient, showcasing innovative engineering solutions such as concrete cornice blocks for arch support and locally produced sand-cement blocks for facing.

There is a popular account about the construction of this bridge. When construction work commenced on the bridge, World War 1 broke out and the steel consignment assigned for this site was seised and used for war-related projects.

The construction of the Nine Arch Bridge was part of a broader initiative to extend the railway from Colombo, the capital of Sri Lanka, to the tea-growing regions in the interior. This extension, beginning at an elevation of 4,100 feet in Bandarawela and descending to 2,000 feet in Badulla, posed significant engineering challenges due to the rugged terrain and numerous waterways that had to be crossed.

The work had been carried by Harold Cuthbert Marwood as Engineer in charge of that section of the railway, under the approval of the Chief Construction Engineer, Railway Extensions, M. Cole Bowen.

Marwood’s report had been submitted to the Institution of Engineers, Ceylon in 1922. You can read the original report here.

Design and Construction

The Nine Arch Bridge is a masterpiece of railway engineering. The bridge spans 400 feet in length and rises to a height of 100 feet 6 inches at its tallest point. It features nine elegant 30-foot spans supported by semi-circular arches, each with a 15-foot radius. These design elements were crucial to accommodating the railway’s nine-degree curve (with a radius of 6.47 chains) and the severe gradient of 1 in 44 at the bridge site.

One of the primary challenges in constructing the Nine Arch Bridge was the foundation. The underlying material, a combination of cabook (a type of laterite soil) and boulders, had to be carefully assessed to ensure stability, especially given the nearby slipping cuttings. As a result, the piers of the bridge were founded well into the slopes of the ravine to distribute the weight and ensure stability.

Innovative Construction Techniques

The construction of the Nine Arch Bridge employed several innovative techniques, particularly given the constraints of the time and the local labor force. The bridge was built using mass concrete in the piers and abutments, mixed in a ratio of 6 parts broken stone, 3 parts sand, and 1 part cement. The arches were constructed from concrete blocks in a 3:2:1 ratio.

To support the arches during construction, concrete cornice blocks were introduced at four-foot centers, projecting beyond the springing face of the piers. This allowed the temporary framing and wedges to hold the arch centers in position securely. These arch centers were struck two weeks after the arch had been turned, a method that significantly reduced the risk of collapse during construction.

Local Labor and Materials

One of the most notable aspects of the Nine Arch Bridge’s construction is that it was carried out entirely by native labor under British supervision. The facing of the concrete was done using sand-cement blocks, measuring 12 inches by 10 inches by 6 inches, produced locally. These blocks were made in molds with a mix of 1 part cement to 6 parts sand, ensuring durability and consistency.

The only major equipment used on-site was a concrete mixer and derricks, with temporary platforms and staging erected to support the construction process. Despite the logistical challenges, including the remote location approximately 170 miles from Colombo, the bridge was completed in 1919, after two years of intensive work.

The Folklore of Appuhami

A popular local folklore surrounding the Nine Arch Bridge attributes its construction to a local builder named P. K. Appuhami. According to the legend, Appuhami, a skilled craftsman, took on the project with a team of local labourers and successfully completed it using traditional methods. This story has been passed down through generations, adding a layer of cultural significance to the bridge.

However, historical records indicate that the project was overseen by Harold Cuthbert Marwood, an English engineer who was the Executive Engineer in the Railway Construction Department. Marwood’s meticulous planning and innovative construction techniques were instrumental in overcoming the numerous challenges posed by the terrain and material constraints. There is no documented evidence to support the involvement of Appuhami in the bridge’s construction, but the folklore remains a cherished part of local heritage.

Legacy and Impact

Since its completion, the Nine Arch Bridge has stood the test of time, enduring the wear and tear of regular railway traffic without significant settlement. It remains a vital part of the railway network and a popular tourist attraction, admired for its architectural beauty and historical significance.

The bridge not only facilitated the efficient transport of tea and other goods from the interior to the coast but also symbolised the innovative spirit and collaborative effort between British engineers and Sri Lankan labourers. Today, it continues to inspire awe and admiration, a true marvel of early 20th-century engineering.

Credit: The Sunday Times, University of Colombo, Mesmerized

Loading…

Loading…